| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Ziitek

Model Number : TS-TIF100C 8045-11

Certification : UL & RoHS

Place of Origin : China

MOQ : 1000pcs

Price : 0.1-10 USD/PCS

Payment Terms : T/T

Supply Ability : 1000000 pcs/month

Delivery Time : 3-5 work days

Packaging Details : 24*13*12cm cartons

Products name : Custom Silicone Thermal Insulation Pads Thermal Gap Filler For Auto Parts&Battery Pack Sealing

Thermal Conductivity : 8.0W/mK

Features : High-Temperature Resistant Flame-Retardant

Hardness : 45 Shore 00

Thinkness range : 0.012"(0.30mm)~0.200"(5.00mm)

Color : Gray

Flam rating : 94 V-0

Keywords : Silicone Thermal Pad

Application : Auto Parts&Battery Pack Sealing

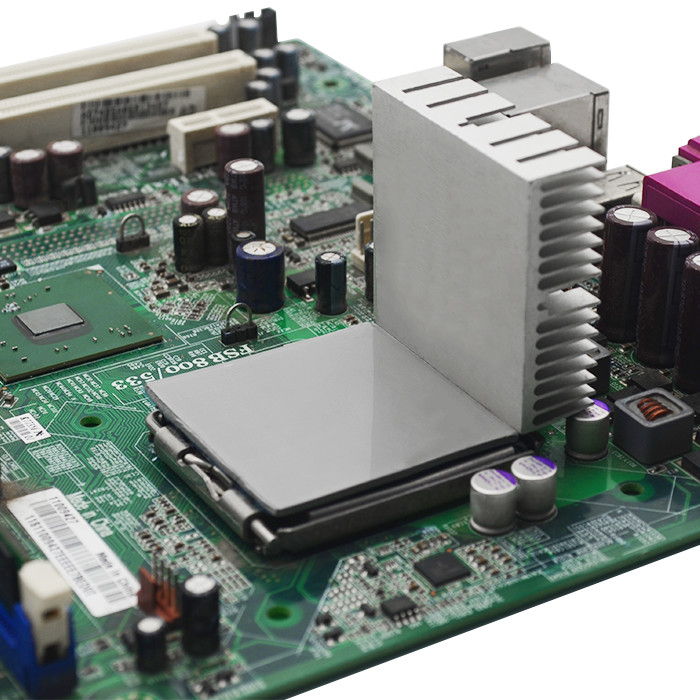

Custom Silicone Thermal Insulation Pads Thermal Gap Filler For Auto Parts&Battery Pack Sealing

Company Profile

Ziitek company is a manufacturer of thermal conductive gap fillers, low melting point thermal interface materials, thermal conductive insulators, thermally conductive tapes, electrically & thermally conductive Interface pads and thermal grease,Thermal Conductive plastic,Silicone Rubber,Silicone Foams,Phase Changing Materials products, with well-equipped testing equipment and strong technical force.

Certifications:

ISO9001:2015

ISO14001: 2004 IATF16949:2016

IECQ QC 080000:2017

UL

The TS-TIF ®100C 8045-11 Series is a silicone-based thermal material designed to fill the gapsbetween heat-generating components and liquid cooling plates or metal bases. lts flexibility andelasticity make it ideal for covering highly uneven surfaces. With excellent thermal conductivity, itefficiently transfers heat from heat-generating elements or PCBs to liquid cooling plates or metalheat dissipation structures, thereby improving the cooling efficiency of high-power electroniccomponents and extending the lifespan of the equipment.

Features:

> Excellent thermal conductivity 6.5W/mK

> Moldability for complex parts

> Soft and compressible for low stress applications

> Naturally tacky needing no further adhesive coating

> Available in varies thicknesses

> Broad range of hardnesses available

Applications:

> Cooling components to the chassis of frame

> High speed mass storage drives

> Heat Sinking Housing at LED-lit BLU in LCD

> LED TV and LED-lit lamps

> RDRAM memory modules

> Micro heat pipe thermal solutions

> Automotive engine control units

> Telecommunication hardware

> Handheld portable electronics

> Monitoring the Power Box

> AD-DC Power Adapters

> Rainproof LED Power

> Waterproof LED Power

> SMD LED module

| Typical Properties of TS-TIF ®100C 8045-11 Series | ||

| Color | Gray | Visual |

| Construction & Compostion | Ceramic filled silicone elastomer | ****** |

| Specific Gravity | 3.4g/cc | ASTM D792 |

| thickness | 0.012"(0.30mm)~0.200"(5.00mm) | ASTM D374 |

| Hardness (thickness<1.0mm) | 45 (Shore 00) | ASTM 2240 |

| Continuos Use Temp | -40 to 200℃ | ****** |

| Dielectric Breakdown Voltage | ≥5500 VAC | ASTM D149 |

| Dielectric Constant | 7.2MHz | ASTM D150 |

| Volume Resistivity | ≥1.0X10¹²Ohm-meter | ASTM D257 |

| Fire rating | 94 V0 | UL94(E331100) |

| Thermal conductivity | 8.0W/m-K | ASTM D5470 |

Standard Thicknesses:

0.020" (0.51mm) 0.030" (0.76mm)

0.040" (1.02mm) 0.050" (1.27mm) 0.060" (1.52mm)

0.070" (1.78mm) 0.080" (2.03mm) 0.090" (2.29mm)

0.100" (2.54mm) 0.110" (2.79mm) 0.120" (3.05mm)

0.130" (3.30mm) 0.140" (3.56mm) 0.150" (3.81mm)

0.160" (4.06mm) 0.170" (4.32mm) 0.180" (4.57mm)

0.190" (4.83mm) 0.200" (5.08mm)

Consult the factory to alternate thickness.

Packaging Details & Lead time

The packaging of thermal pad

1.with PET film or foam-for protection

2. use Paper Card To Separate Each Layer

3. export carton inside and outside

4. meet with customers' requirement-customized

Lead Time :Quantity(Pieces):5000

Est. Time(days): To be negotiated.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are manufacturer in China.

Q: How long is your delivery time?

A: Generally it is 3-7 work days if the goods are in stock. or it is 7-10 work days if the goods are not in stock, it is according to quantity.

Q: Do you offer free samples ?

A: Yes, we are willing to offer free sample.

|

|

Custom Silicone Thermal Insulation Pads Thermal Gap Filler For Auto Parts & Battery Pack Sealing Images |